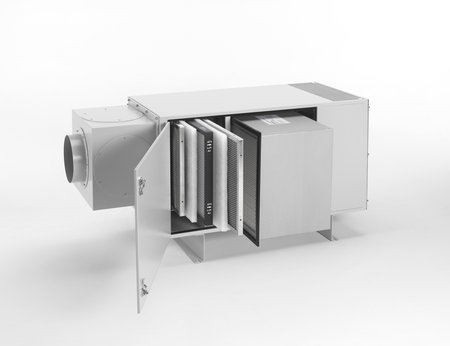

Air cleaning device AFS 1100_EC

Air purifier AFS 1100, EC version

- Box unit with intake opening left / right (please specify when ordering)

- ready for installation / mounting on a machining center

- with feet incl. incl. (U-profile 120 mm)

- Including suction funnel with hose connection Ø 200 mm

- all filter elements and connection for cooling lubricant return

- Color: RAL 7035 textured paint

- Air volume: 1,100 m³ / h (appliance air output).

- Rated electrical data: EC motor 3 ~ 380 ... 480 V, 50/60 Hz, 1.3 kW,

- 2.0 A, IP 55

- Power consumption at operating point: 0.5 kW, 0.83 A

- ErP compliant 2015

- Electrical connections on site

Annotation:

- Noise level 65.5 dB (A)

- Weight approx. 80 kg

In addition:

- On / Off switch (Rep-switch)

- 6 mtr. Siphon hose ½ "

- Connection piece Ø200 mm RAL 7035

- 3 mtr. Flexible hose Ø200 mm

- 2 quick-release clamps Ø190-210 mm

Optional: (at additional cost)

- CEE plug CEKON 16 A, 400 V

- 5 mtr. Cable to Cekon connector

Costs for packaging and forwarding transport updated daily only on request

AFS single units are a well-defined solution for a particular application and can be placed directly on or at the machine tool.

The AFS air cleaning unit and processing center form a unit. This means a high degree of flexibility in the installation of machinery and the rearrangement of machines. AFS individual units require little installation effort and usually only short tubing.

AFS single units are used in recirculation mode. This means that the cleaned air is blown directly back into the production hall.

The quality of the purified air meets the legal requirements for the recirculation mode throughout the entire year. The statutory requirements for the cooling lubricant concentrations of the production hall air at work are strictly adhered to.